What You Will Learn with the ChainSim Simulation

ChainSim enhances learning in Production, Logistics, and Supply Chain Planning by immersing students in realistic, end-to-end business scenarios—without real-world risk. Through hands-on experimentation, learners gain practical experience, while instructors benefit from stronger teaching effectiveness and clearer assessment of student performance and development.

By completing the five-level ChainSim course, students will be able to:

Strategic & Managerial Skills

-

Apply general management knowledge to practical business situations

-

Think systemically, recognizing that decisions impact the entire supply chain

-

Improve decision-making skills, both individually and in team environments

Supply Chain & Operations Management

-

Define core supply chain concepts and managerial processes

-

Understand the framework and key issues in supply chain and production planning

-

Measure costs and performance across the entire supply chain

-

Optimize procurement, inventory management, and logistics costs

-

Evaluate suppliers, choose sourcing strategies, and optimize total cost structures

Manufacturing & Lean Practices

-

Analyze a firm’s manufacturing operations

-

Apply Lean tools to reduce costs and improve operational efficiency

-

Test and implement Lean manufacturing principles, including:

-

Just-In-Time (JIT)

-

Level scheduling

-

Continuous flow

-

Analytical & Planning Capabilities

-

Develop analytical methodologies for supply chain analysis

-

Practice material requirements planning (MRP)

-

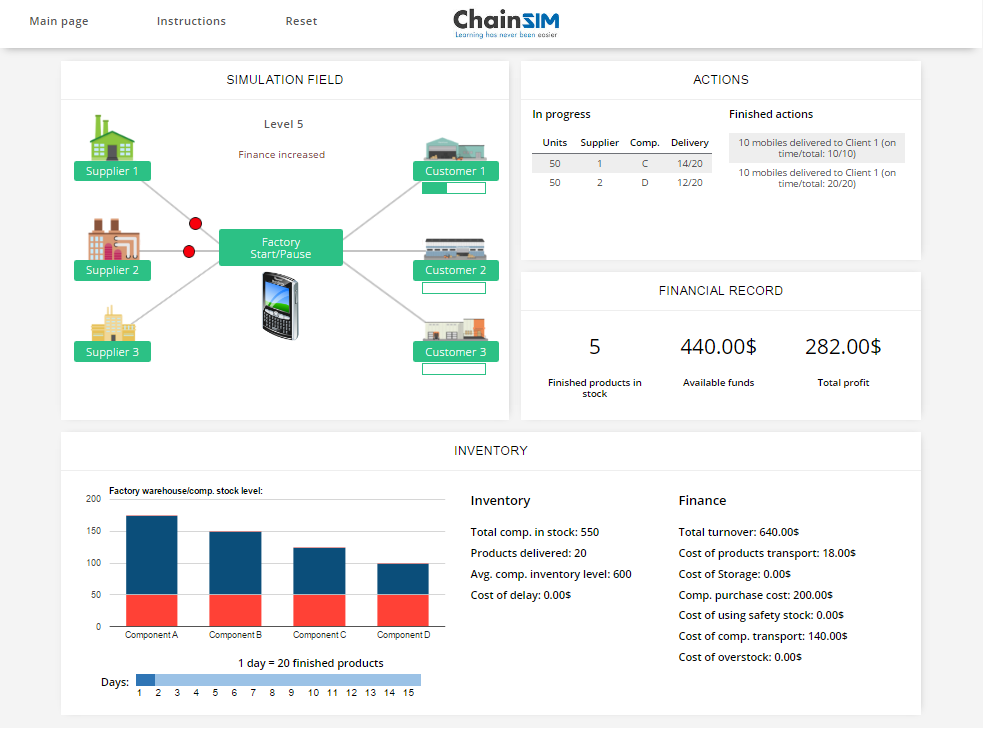

Connect theoretical concepts to real performance metrics, including:

-

Financial results

-

Inventory levels

-

Service performance

-

Experiential Learning Advantage

ChainSim allows students to experiment, pause, analyze, and reflect—a unique advantage over real-world operations. This controlled environment enables deeper understanding, better-informed decisions, and a direct link between actions and measurable outcomes.